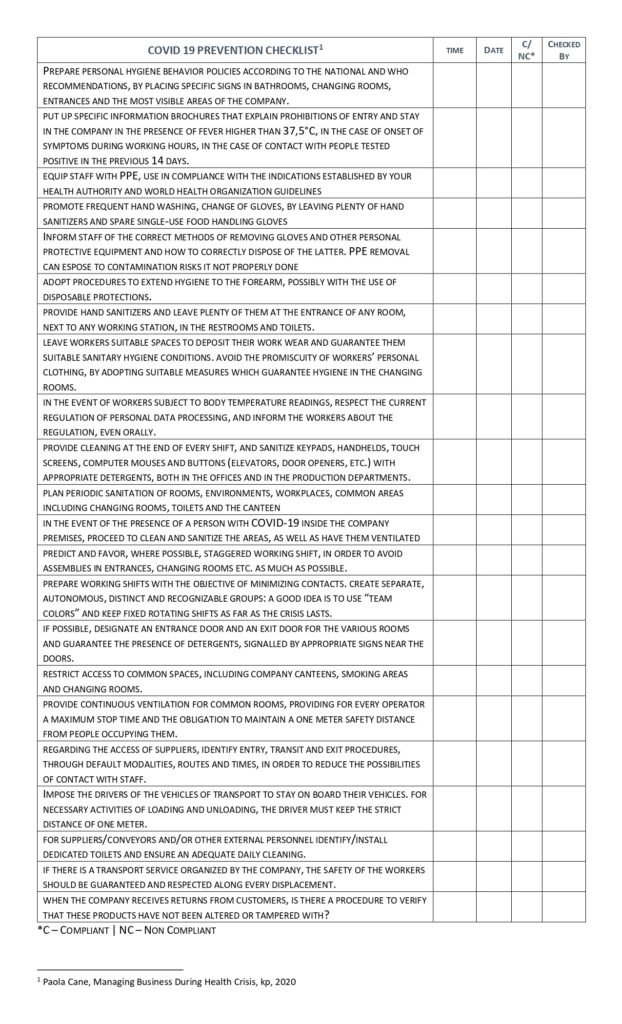

It is time to progress from a reactive mindset to a proactive one. We have been living in a place of fear, where we as humankind are reacting to the new circumstances doing our best to minimize human loss and infection. It is time to take what we already know (science based) and develop the best prevention strategies to mitigate the spread of COVID-19 amongst essential food industry workers … not only as consequence of their work activities, but also in their personal lives.

As COVID 19 has wrought havoc around the world, these past few months have seen more upheaval than many of us could have imagined. The food industry community spans continents, cultures, and sectors, but a shockwave like this reminds us just how intimately connected everyone really is.

As the entire world braces for even more devastating impacts from COVID-19, images of empty grocery store shelves have laid bare the reality that—when modern society comes to a screeching halt—food remains essential. Even amidst the throes of the current crisis, there is no question that transforming our food system will be central to mitigating the risk of future pandemics. Food Safety Professionals are central to that equation.

The COVID-19 pandemic has impacted consumers and businesses around the world. The food industry is playing a critical role in continuing to provide a safe food supply to consumers while mitigating risk of the novel coronavirus, SARS-CoV-2

Though social distancing measures have helped to flatten the curve in the spread of COVID-19, we are not “out of the woods” yet. With food companies having faced closures due to outbreaks at their facilities, the supply chain will be dealing with the effects of COVID-19 long after the height of the pandemic. As health experts warn of a possible rebound in the fall, now is the time to assess what the food industry has learned from this “new normal” and how companies can be prepared to face the challenges of another outbreak.

It is time to progress from a reactive mindset to a proactive one. We have been living in a place of fear, where we as humankind are reacting to the new circumstances doing our best to minimize human loss and infection. It is time to take what we already know (science based) and develop the best prevention strategies to mitigate the spread of COVID-19 amongst essential food industry workers … not only as consequence of their work activities, but also in their personal lives.

The food industry, and particularly their leaders, must take care of their workers by providing them the information, personnel protective equipment and training they need to remain safe (also outside their working facilities).

As hundreds of thousands of human lives were lost so far it will always be difficult to look back and feel we were successful. Success unfortunately in this case cannot be measured as no deaths but as doing all that is in our power (and with what we collectively know and learn in real time) to reduce the spread of the virus.