Auditors will be increasingly required to focus on understanding process-based auditing and to conduct real time risk assessments. Auditing prescriptive requirements and check–lists will be less important in the future.

Auditors will be increasingly required to focus on understanding process-based auditing and to conduct real time risk assessments. Auditing prescriptive requirements and check–lists will be less important in the future.

Market needs are continuously evolving and some events or extraordinary context (our current ongoing COVID 19 pandemic and its disruptive cascading systems failures) as a catalyst for change. Conformity assessment bodies (CABs) are amongst the ones who are quickly confronted with new expectations and needs. CABs are typically quite keen on making efforts to contribute to the widespread change in processes, values and minds required by the new context; obviously because they have a direct impact on their line of work.

As mentioned, many certified companies are using new technologies for their production processes, making use of each and every innovation opportunity which can contribute to better and safer products and services; thereby providing a competitive edge on the market. They are already requesting audits and inspections to take place without any substantial human interference or any disruption to the process or object under evaluation. For this goal, technology is capable to provide appropriate solutions.

The first remedy that seems to spring into peoples’ minds when addressing the impact of technology in conformity assessment is remote auditing which includes digital reporting, paperless management systems or customer relationship management software (CRMs) that allow on-line communication and exchange of information to and from clients. This is a fair conclusion, but this is actually far from being accurate or even new.

It seems that we have come a long way in a short period of time, not just through intense reactions to the restrictions and disruptions imposed by the pandemic outbreak, but also because we were not caught totally off guard. Digital transformation in the conformity assessment business started, in a comprehensive way, many years ago, although I admit that the use of some related tools and processes that are now common in many schemes were residual back then.

Specifically for remote auditing, CABs worked with clients, with Accreditation Bodies (ABs) and Certification Program Owners (CPOs) to conduct evaluations and assessments via remote technology. This allowed, for example, hundreds of thousands of certifications to be maintained so that most organizations could emerge into a new normal with their competitive advantages intact. This also permitted an adequate level of overview and follow up, allowing Non-conformities (NCs) to be identified and corrected as well as improvements to be implemented.

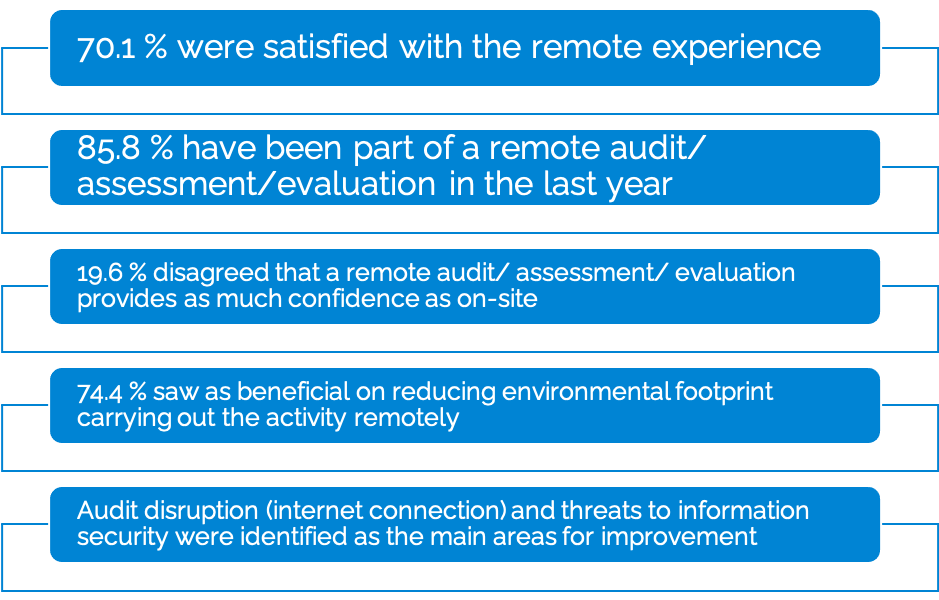

In fact, a very recent joint IAF/ILAC/ISO survey=1 of more than 4000 participants showed that a large majority of respondents prefer remote or blended audits, assessments, and evaluations, feel that remote activities may provide as much confidence as on-site. Moreover, most would like to see a continued or increased use of remote activities in the future.

Again, this approach requires new services, the adoption of technology for improved (and more effective) service provision processes and the development of new competences amongst other relevant aspects.

Some key findings from the survey:

In the food industry, technology supported mass production, better process measurement and quality control and examples could be given on how the use of AI and big data will allow for better food and environmentally friendly agriculture, by reducing the use of pesticides and fertilizers, or using drones for precision farming.

I still remember milk and bread being delivered to our doorstep. The food value chain is no longer that linear. In fact, food supply chains are now very long, deep, and complex, all the while ensuring food safety and trust. In this context, without the use of technology would be disappointing and ineffective to say the least.

With the use of technology is possible to look deep into the supply chain, to better understand where materials and food originate, whilst impacting food safety via verifying and assuring compliance (with regulations, corporate requirements or consumer needs and standards). Moreover, social accountability related issues, such as environmental protection, and sustainability may be also verified which are so important for consumers.

CABs are in the business of creating trust, and this is oftentimes based on what can be collected with human senses, notably observations or surveying, documentation, work performance, an object such as product or equipment, or looking into the eyes of a person during an interview. It is commonly referred in the food safety industry that you need to “smell the factory”. We also need to find ways of creating trust without relying solely on our senses.

However, one cannot overlook the fact that many scheme owners or CPOs (with notable exception of FSSC 22000) still oppose the introduction of non-traditional audit activities (such as remote auditing), regardless of the extensive experience collected through ISO 22000 certification.

Some may point out the work conducted (in due time) through international forums (e.g. IAF*2 e ISO CASCO*3 ) acted as a fundamental trigger for a debate on the further use of technology in food safety related conformity assessment activities. This effort will be maintained, both at a global level through UNIDO’s and IAF’s working groups dedicated to producing general food industry guidance via the creation of a GFSI’s CB2B Group which aims to bring together manufacturers, big brands, retailers and CABs, whilst focused on addressing common relevant issues, amongst which the use of technology and data will be surely included.

I’m truly convinced that through appropriate data processing, retailers, manufacturers, CPO, ABs and CABs can tailor control plans or assessment programs to the unique characteristics and nature of each organization, and measure performance and risk of each specific situation. As so, technology and data can make auditing a relevant and efficient exercise with an impact not only on food safety through verifying and assuring compliance, but also on Social Responsibility related issues and environmental protection and sustainability, so important for consumers.

I agree that it certainly requires addressing data consistency and quality, and how to collect it. Data is the key. It requires technology, collaboration and trustworthy | secure inputs and access. With appropriate data, risk and food safety can be better addressed, supporting transparency to the market, contractual relationships and procurement, the investigation of claims and incidents (such as product recalls), and through conformity assessment, progress in reducing uncertainty and creating trust.

It’s not just providing adequate tools so that auditors can do their job in a technology focused environment (such as using remote auditing tools or using drones for inspection purposes), it’s about redefining the structure, skills, and task attribution of audit teams, (for example, through the consolidation of new audit team member profiles).

Auditors will be increasingly required to focus on understanding process-based auditing and to conduct real time risk assessments. Auditing prescriptive requirements and check–lists will be less important in the future (these activities will be more efficient when automated).

Auditors need to be skilled not just in using the available technological tools, but in data analysis (or have someone within the audit team to assist them). These can be Junior auditors, less experienced in auditing food safety management systems requirements per se but highly skilled in analytical data analysis, data mining, scrubbing and mapping. These tech skills support the Lead auditor by providing a set of presentatable digested data information for better decision making, for audit findings support and evidence, for assessing food safety performance or supporting pre-audit risk assessments.

I also believe that auditors will need to be qualified for cross-functionality in more than one management area (not just food safety but also, as mentioned, on environmental and social responsibility issues). Auditors should consider becoming competent in more than one technical area (to be able to look further, to address supply chain issues, etc.)

In the words of one of IQNET’s representatives to food safety international forums (Colin Christmas who is the co-convenor of IAF Food WG), “process thinking, critical thinking, risk based thinking and integrated systems thinking will be the future food safety auditor mind set”. Additionally, when we can provide auditors with these adequate tools that will significantly increase the probability of their work to be facilitated successfully, to continue to be effective and of value in the future context (as I firmly believe it is already the case).

Most of the issues I addressed and my opinions on them are supported by recent debates taking place in the food industry, in accreditation and other forums (some of them are actually progressing as we speak) with a fundamental belief that all players have to address the new context as a matter of survival:

Technology based activities are not designed to completely replace traditional activities. Furthermore, technology certainly will not provide all the answers and solutions for each particular case. However, I don’t have any doubts that, all stakeholders, to stay relevant, will have to be able to make the huge leap in accepting and further developing new methods to create trust, starting here and now.

This article was written by Pedro Castro Alves, Managing Director @ IQNET Association.

Contributing Editor: Jocelyn C. Lee, Food Safety Consultant

*1 https://iaf.nu/wp-content/uploads/2021/10/Summary-Report-IAF-ILAC-ISO-Remote-Survey.pdf .

*2 https://iaf.nu/wp-content/uploads/2021/08/IAF_Food-WG_Remote-Auditing_FINAL_030821.pdf

Disclaimer: The information contained on this article is based on research done in the last months and the authors personal experience and opinion. It is not intended to represent the view of any organization they work for or collaborate with. The authors will not be held liable for the use or misuse of the information provided in the article.