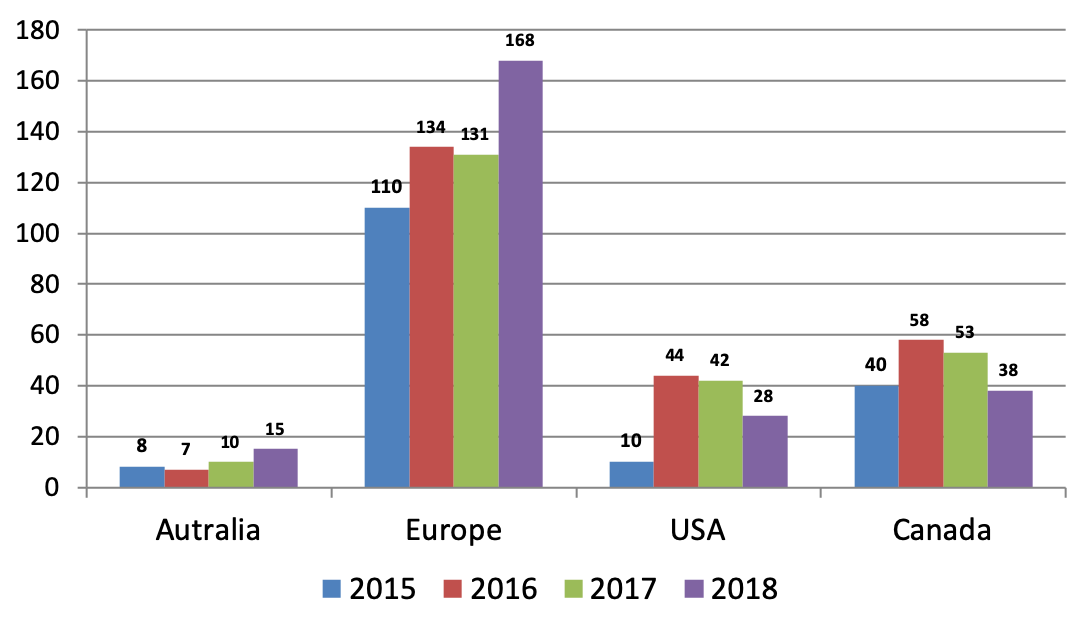

Importance and statistics

Globalization of the food industry has allowed for a more expansive food network that allows for food products from distant areas to reach different parts of the world. Food production, consumption, transportation, and the entire food chain have changed drastically over the past few decades and population growth and advances in technology will continue to drive additional changes. By expanding the food industries reach of products and services we also potentially increase the opportunity for foreign material contamination as well.

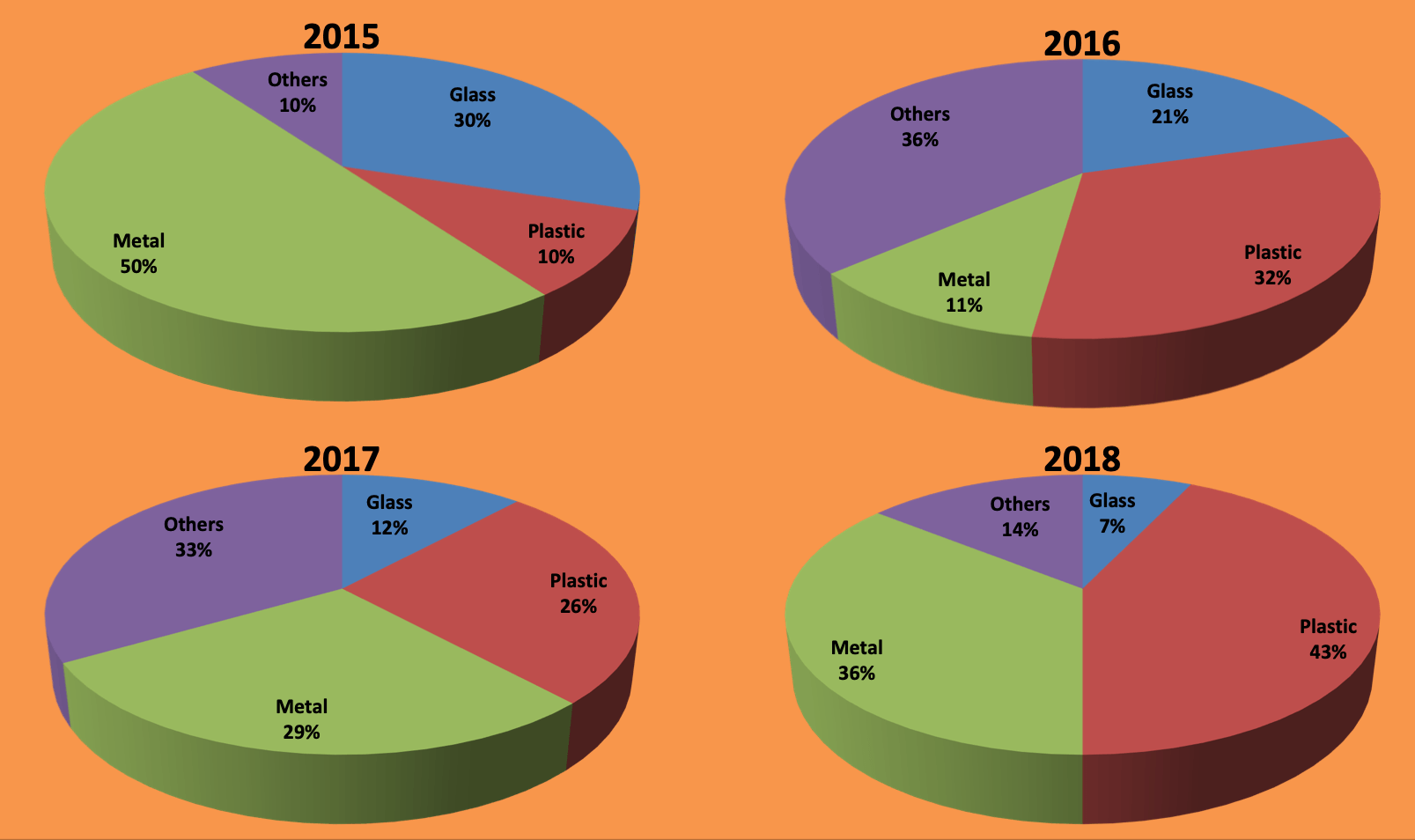

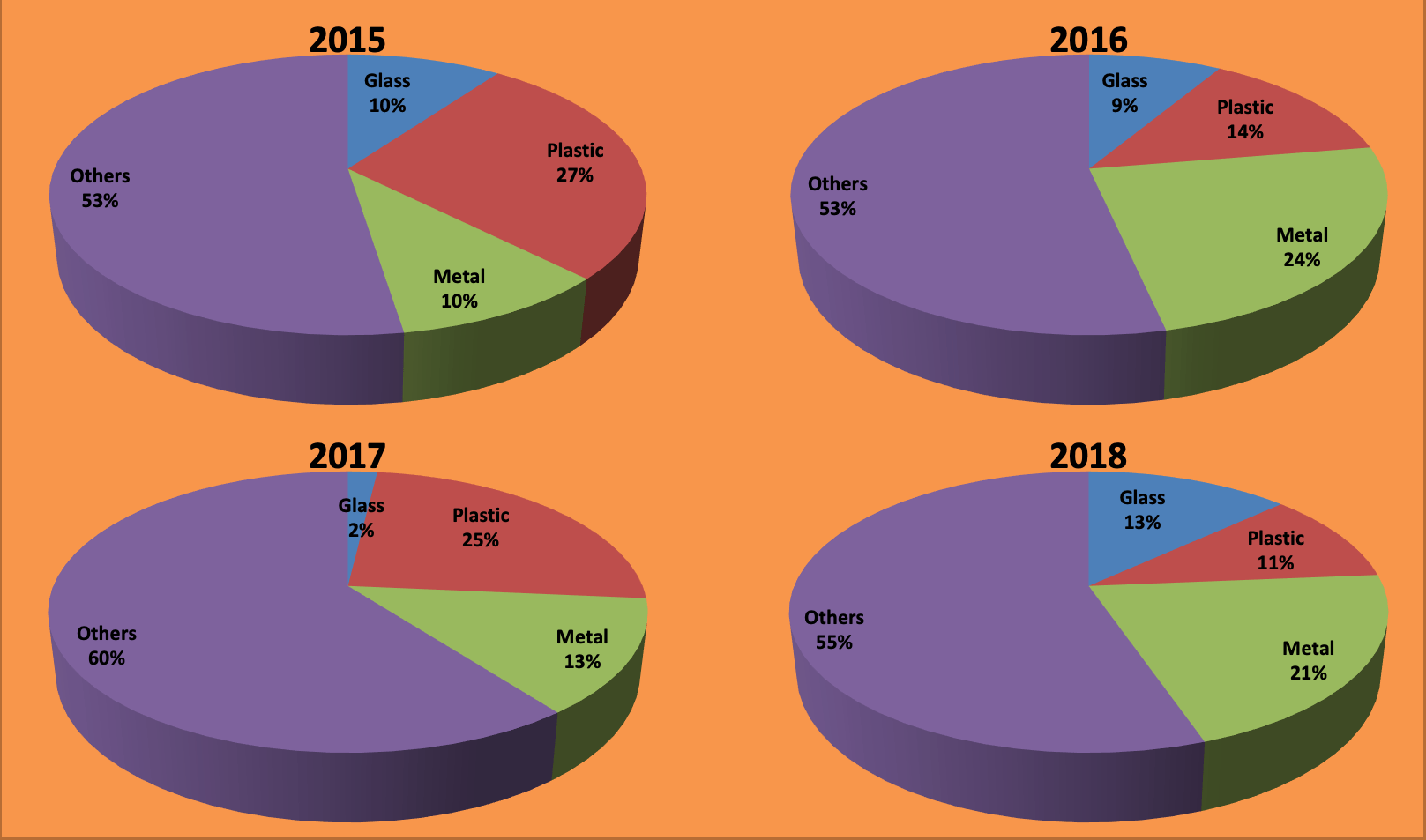

Foreign material of any kind can potentially introduce a physical hazard in a food product. These range from natural sources such as rocks, wood, or product components such as shells or bones, to processing components such as metal shavings, equipment parts, or glass pieces from packaging materials. Other potential foreign materials can also be introduced to the finished product at many stages throughout the production of the food such as broken light bulbs, operator contamination, or pest contamination. Ensuring a product is safe from physical hazards, it is generally completed by multiple steps throughout the production process with added attention at Critical Control Points.

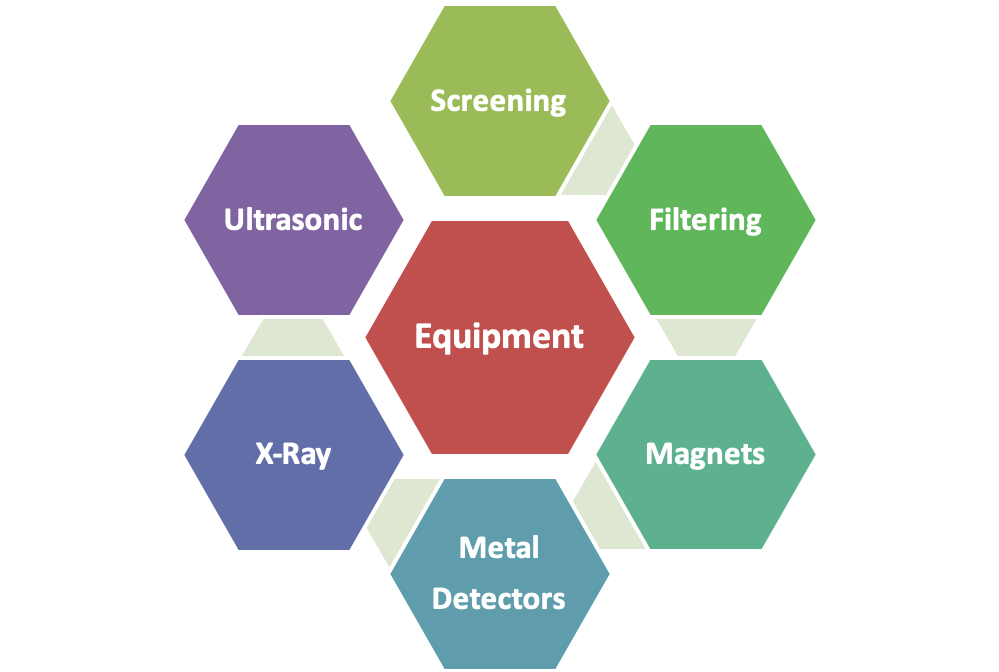

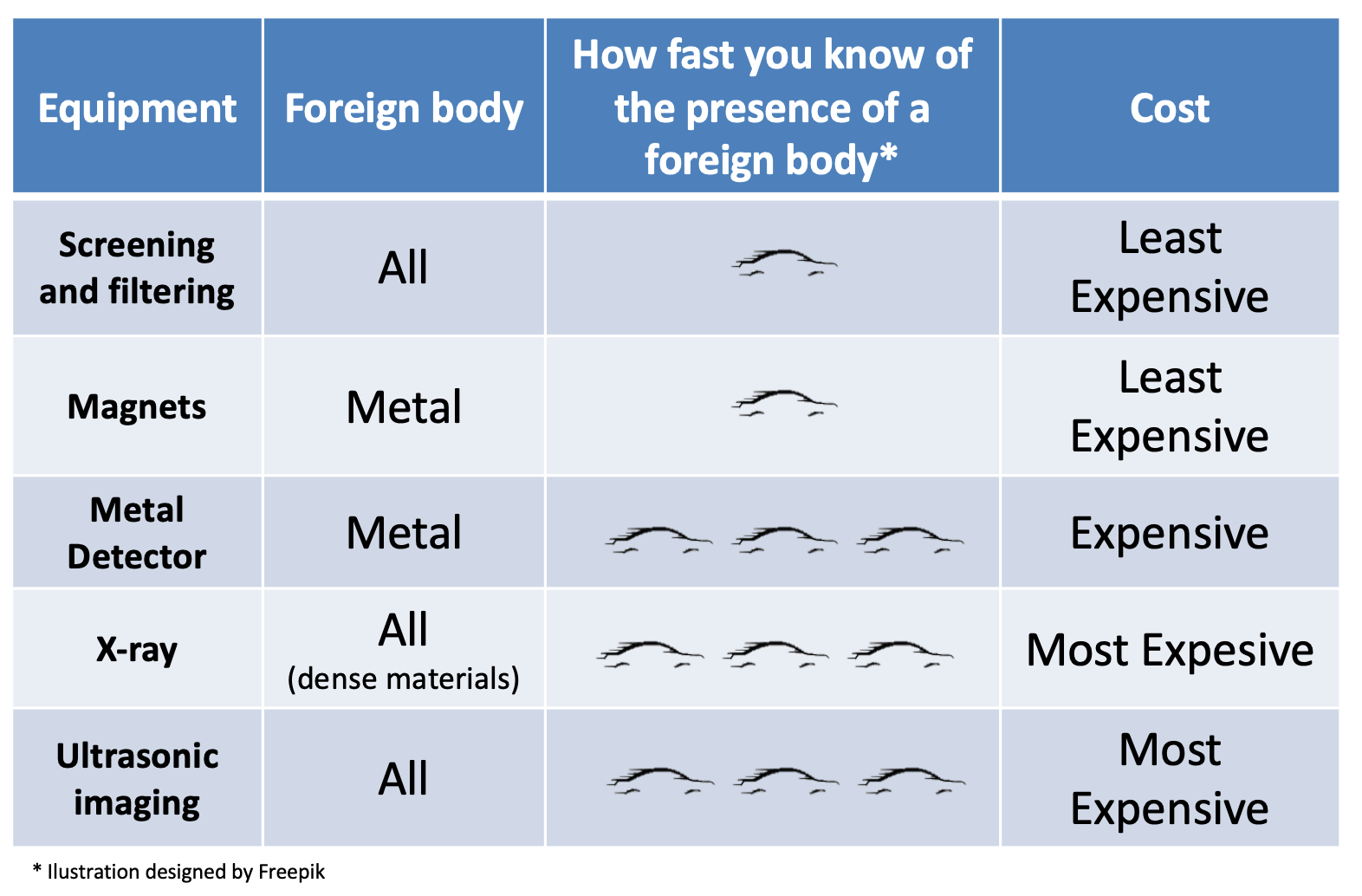

Various programs such as pest control programs, good manufacturing programs, foreign material control, receiving and material control programs, and various other programs help lay the foundation for ensuring no physical contamination occurs. In this article, we shall be reviewing a few existing methods that are currently used to control foreign material as well as some relatively modern innovative technologies that may be implemented.