Glass fragments can lead to serious injuries and for this reason food safety professionals should include in their food safety systems glass policies.

Glass fragments can lead to serious injuries and for this reason food safety professionals should include in their food safety systems glass policies.

While only 5% of incidents with foreign materials result in injury (Hyman et al., 1993; Olsen, 1998), food safety professionals must have particular attention to sharp objects that can cause oral or gastrointestinal lacerations or perforations.

When consuming food, it is generally understood by consumers that certain natural components, such as bones in seafood or shells in nut products, are present and may require caution. Consumers are aware that these components are intrinsic to the particular food product and are less likely to cause injury because they anticipate their presence.

However, there are exceptions when it comes to foods that are specifically labeled as having the hard or sharp component removed. For example, pitted olives are marketed with the claim that the pits have been taken out. In these cases, consumers expect that the naturally occurring hard or sharp object, such as pit fragments, will not be present in the food. Therefore, if any remnants of the hard or sharp component are unexpectedly found in these foods, it can catch consumers off guard and potentially lead to injury.

It is important for food manufacturers and distributors to accurately represent the absence or removal of hard or sharp components in labeled products to ensure consumer safety and avoid any unexpected harm. Clear labeling and quality control measures play a crucial role in preventing potential injuries caused by the presence of these natural components in foods where their absence is expected.

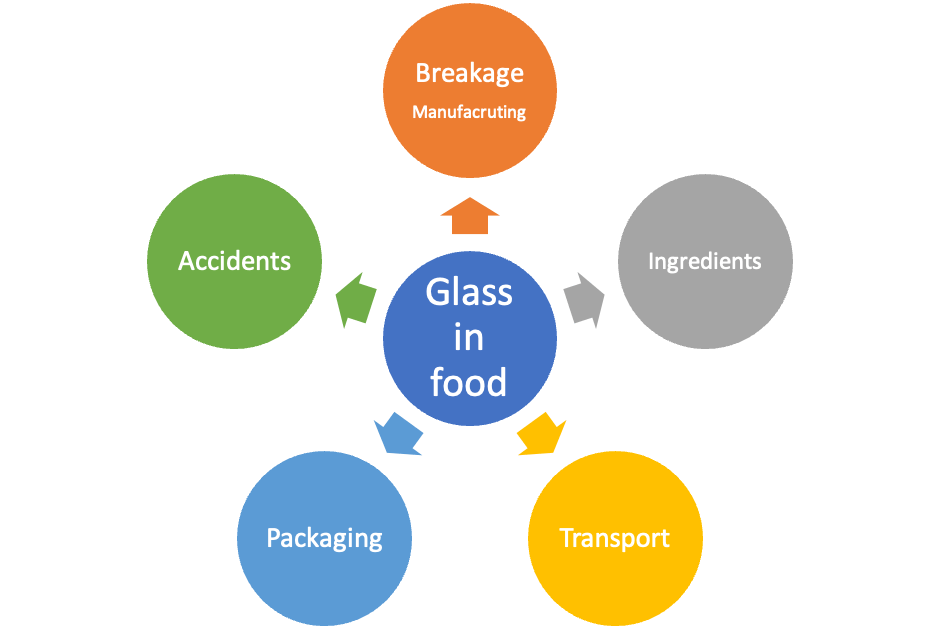

Glass fragments can end up in food through various means, often as a result of accidents or mishandling during food processing, packaging, or transportation. Here are some possible scenarios:

It is important for food manufacturers to implement strict control measures, including proper inspection and monitoring, to prevent glass contamination. This includes regular equipment maintenance, thorough ingredient inspections, and robust packaging protocols. Additionally, food handlers and operators should maintain a clean and safe working environment to minimize the risk of glass fragments ending up in the food.

The steps to establish this policy may be:

Some measures to prevent contamination with glass fragments include shielding lights, such as coating light bulbs, and protecting the surroundings and products when changing lights. It is important to note that lights, as well as other brittle materials, are also present in forklifts, tunnels, and freezers, among other areas within the facility.

In addition, it is crucial to implement a monitoring procedure to regularly assess the condition of any glass materials still present in the facility, even if they are already shielded. The frequency of monitoring should be determined based on the level of risk. It is recommended to conduct the monitoring at least monthly in areas where the risk of glass contamination is higher.

https://www.fao.org/documents/card/es/c/b809f8d5-ceba-4c44-9ff5-c2f8ab601666/

This article was written by:

Nuno F. Soares

Contributing Editor: Jocelyn C. Lee, Food Safety Consultant

Disclaimer: The information contained on this article is based on research done in the last months and the authors personal experience and opinion. It is not intended to represent the view of any organization they work for or collaborate with. The authors will not be held liable for the use or misuse of the information provided in the article.