Who hasn’t felt nervous before an audit?

There is so much pressure today on food safety professionals to accomplish successfully audits, especially when we have a big client requiring it or a Certification Body doing it. Most of us neglect the fact that audits should be perceived as one (more) powerful tool in the continuous improvement of our food safety system.

AUDITS

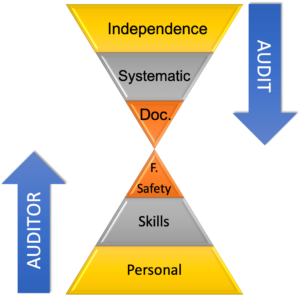

What is an audit? Probably one of the most common and used audit definition is the one provided by the ISO 19011 – Guidelines for auditing management systems. In its last update (2018) the ISO document defines audit as systematic, independent, and documented process for obtaining objective evidence and evaluate it objectively to determine the extent to which the audit criteria are fulfilled. In this definition ISO decided to reinforce the importance of the evidence being objective since the only change from the 2011 definition was the substitution of audit evidence for objective evidence.

More details can be found in the GFSI definition for audit present in the GFSI Benchmarking Requirements version 7.2: A systematic and functionally independent examination to determine whether activities and related results comply with a conforming scheme, whereby all the elements of this scheme should be covered by reviewing the supplier’s manual and related procedures, together with an evaluation of the production facilities. Clearly in common we have that audits should be systematic and independent process to determine compliance with criteria.

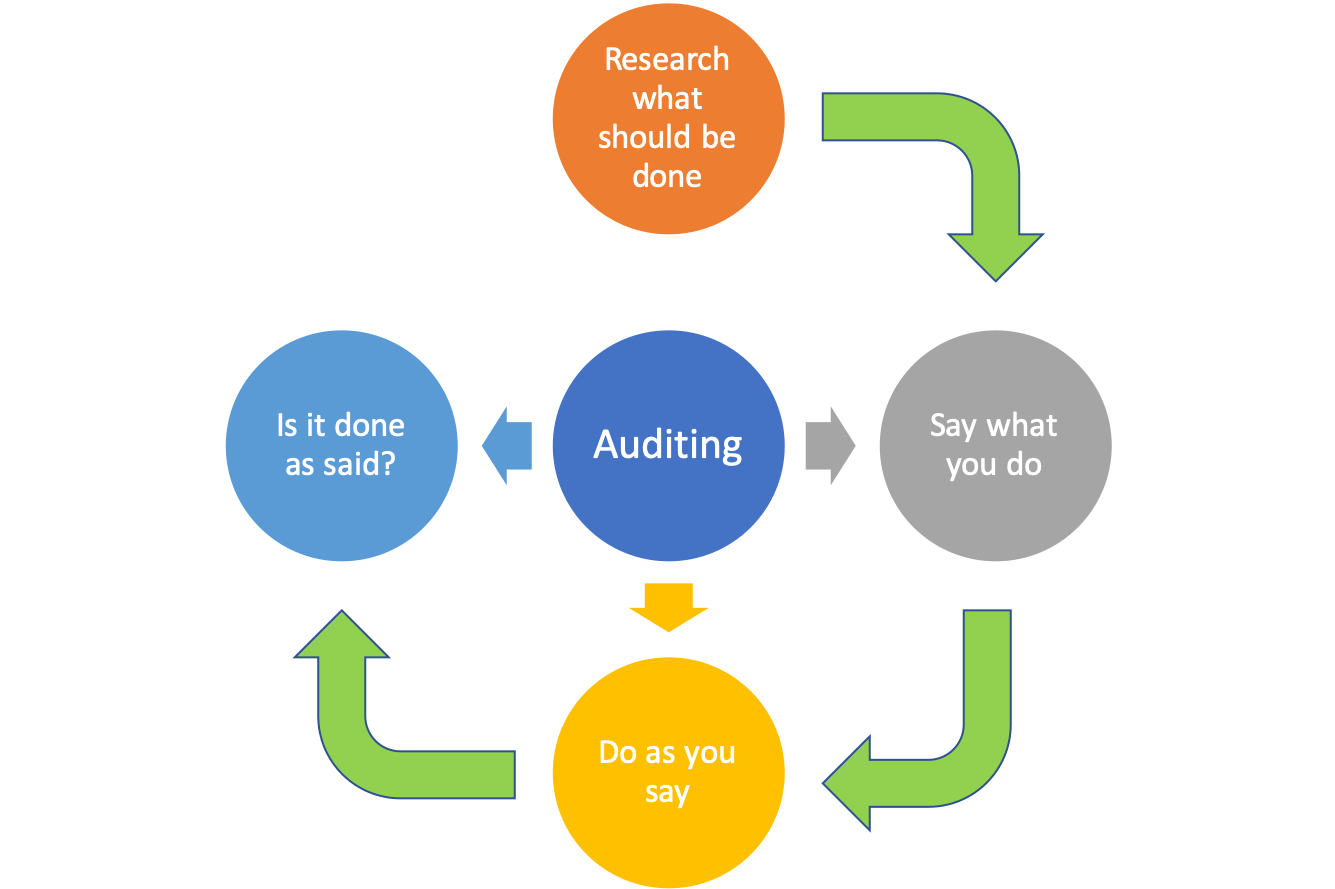

As a systematic process, auditing has two main roles:

1- Validating that the food safety systems are thought and built to fulfill the criteria

2- Verifying that the activities performed comply with what is planned and are effective.